The following considerations factor into calculation of the AOR. Design Flows and Loads.

Arris 2212 980kv Brushless Motor Thrust And Power Calculations Motor Speed Quadcopter Build Power

P Engine Cruise P Req η P E n g i n e C r u i s e P R e q η If we assume that the efficiency η085 η 085 then we can calculate the engine power required.

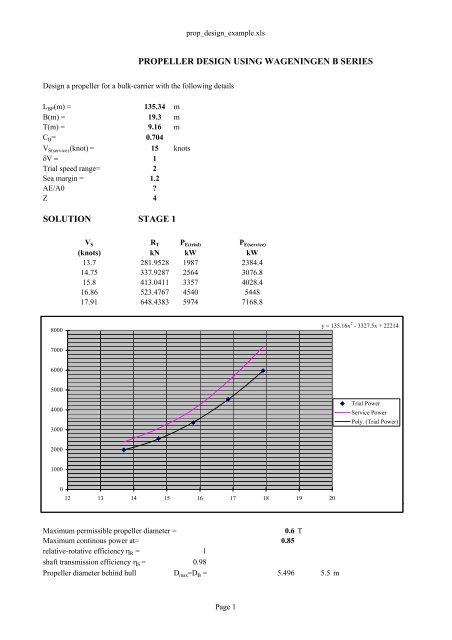

. Design a propeller for a bulk-carrier with the following details. â Design apron and parking areas outside AOA critical areas considering parked positions aircraft maneuvering within the apron and entryexit movements to the airfield. A Bp- diagram or experience might be used.

A Bp-δ diagram or experience might be used. Some software includes kinematic capabilities that simulate vehicle dynamics using the designed suspension. Calculation of thrust and torque 1.

The propeller design calculation consists of three steps. The propeller design calculation consists of three steps. Select propeller diameter and RPM.

20 Turbine Design Spreadsheet The design procedure follows a series of logical steps. Unsurpassed in hydrodynamic design and analysis of ships. T m 916 m.

The drag polar is a fundamental aspect of aircraft design and performance analysis. UTmean UAmean Cxzbi Goldstein factor from diagram blades UT UA VA n Hz Lift Nm CL Rn Blade section lift coefficient Dimless radius. Now to complicate matters static thrust is proportional to the exit velocity squared so in this example the 2-bladed prop would produce 142 196x as much thrust as the 1-bladed prop the 3-bladed prop would produce 162 256x as much thrust and the 4-bladed prop would produce 172 289x as much thrust.

Trial speed range 2. Check of risk of cavitation 3. B m 193 m.

Determination of camber and pitch distribution Calculation of thrust and torque 1. The Drag Polar Marine Electrical Load Analysis Spreadsheet or reset password. Design 5 3d characters 12500-37500 INR Technical Animation 3D design 30-250 USD Finite element analysis -- 2 10-30 USD calculate two drone setups given thrusts and position of each of the rotors 30-250 EUR Make me a pair of neural headphones 750-1500 GBP.

Check of risk of cavitation 3. C B 0704. Propeller design calculation Diam kinvisk n pa pv rho_s z r k m a Vs knots T kN RPM D m w c xx G Circulation distribution parameters.

If we assume that the selected propeller is designed to be most efficient at the designated cruise speed then the required engine power is determined as follows. Aliquot 180 µl of protein stock solution into a microcentrifuge tube and make a series of eight two-fold dilutions into protein dilution buffer by sequentially mixing 90 µl of buffer with 90 µl of the. The design approach should be implemented in a preliminary tool either software or spreadsheet based for blast response.

Propeller design calculation Diam kinvisk n pa pv rho_s z r k m a Vs knots T kN RPM D m w c xx G Circulation distribution parameters. Calculation of thrust and torque 2. The flow chart on page 3 outlines the stages in the design procedure.

V S service knot 15 knots. Then this rotating motion becomes a forward thrust force by the propeller that feeds the aircraft forward and is required to balance the drag produced by moving. SHP BHP 097 100 - 0015 number of bearings 100 Displacement in pounds.

Starting from the site data the turbine speed should be chosen to give a specific speed which fits with the. Propeller Design and Propulsion Concepts for Ship. Empirical formula Chord length.

PROPELLER DESIGN USING WAGENINGEN B SERIES. V V U A 2 2 rn - T 2 2 2 13. Submarine Design 78 Apron Planning and Design Guidebook Key Points.

NB Each extra gearbox or vee-drive will reduce power by an additional 3. Aircraft propeller design calculation spreadsheet pdf file download online Nearly all unemployment agencies accept claims online especially in light of the COVID-19 pandemic. Stability Calculation for an existing Barge If you have an existing barge for which the following.

Select propeller diameter and RPM. L BP m 13534 m. Demo data already entered.

20 Turbine Design Spreadsheet The design procedure follows a series of logical steps. Determination of camber and pitch distribution. Aircraft propeller design calculation spreadsheet An internal fuel engine is designed to convert the reciprocating movement of the pistons into rotating movement on the crankshaft.

KEY The purpose of this spreadsheet is to take the guesswork out and produce a spec that is as close as Indicates data requiring input by you. Calculation of thrust and torque 2. The optimized value of clm 0482 is located around the left boundary of the region for allowable design.

â Identify runway and taxiway critical areas that may affect apron. Up to 24 cash back Aircraft propeller design calculation spreadsheet example answers answer On the other hand as altitude increases the rotational speed of the propeller gradually increments which consequently results in an increase of the required power. Welcome to the Surfbaud Freeware Propeller Calculator for Excel.

The calculations for each step have been put into the spreadsheet. Select blade section thickness and camber. The calculations for each step have been put into the spreadsheet.

Wageningen B Screw Series Propeller Design

Propeller Blade Thickness Calculation Spreadsheet Www Thenavalarch Com Youtube

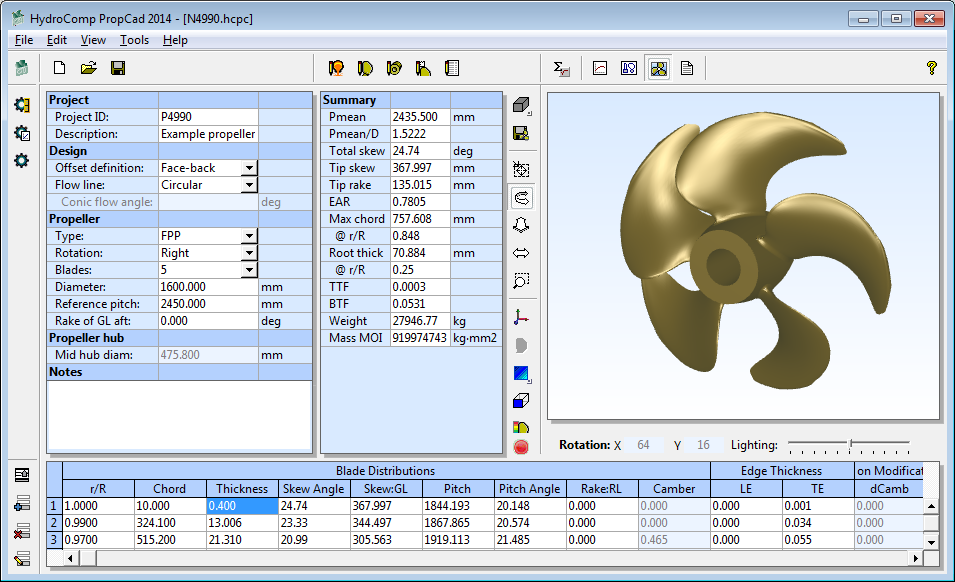

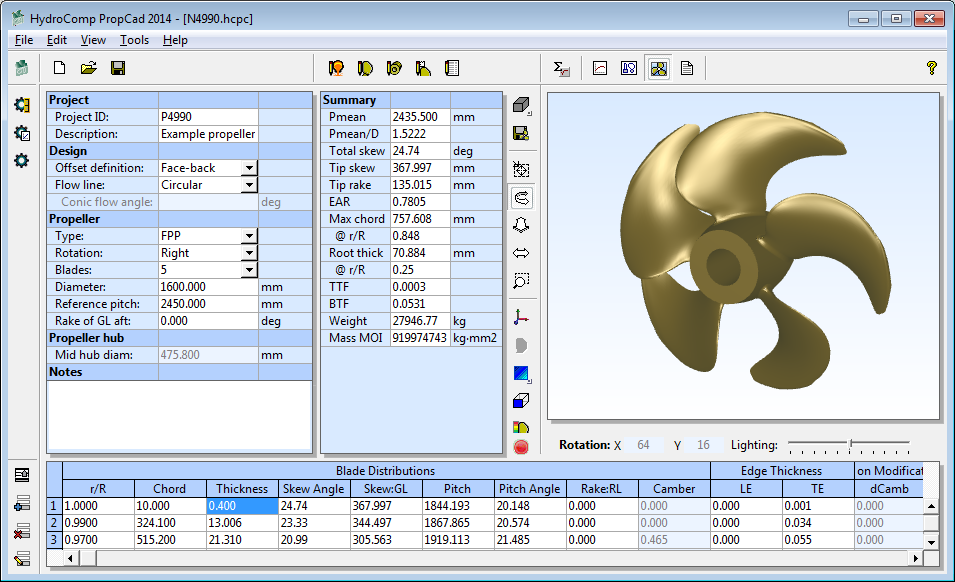

Propeller Design Software Upgraded

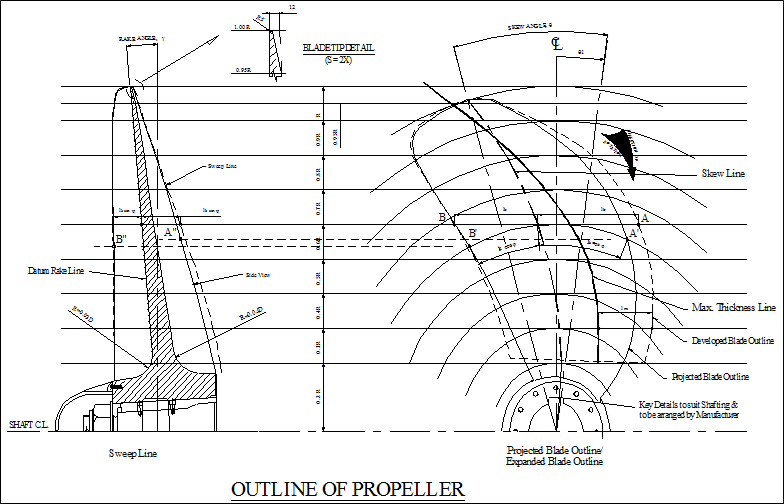

Propeller Design Calculation Results Download Table

0 comments

Post a Comment